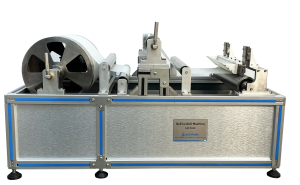

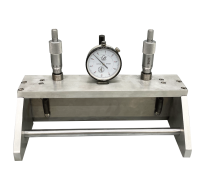

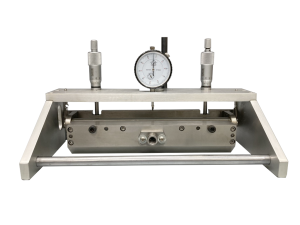

At AccuPore, we offer a comprehensive suite of membrane system products designed for lab-scale experimentation, pilot studies, and full production environments. Our flat sheet casting systems include versatile configurations such as roll-to-roll, slot-die, and doctor blade coaters, each engineered for fine control over film thickness, drying, and speed—making them ideal for both research and pre-commercial trials.

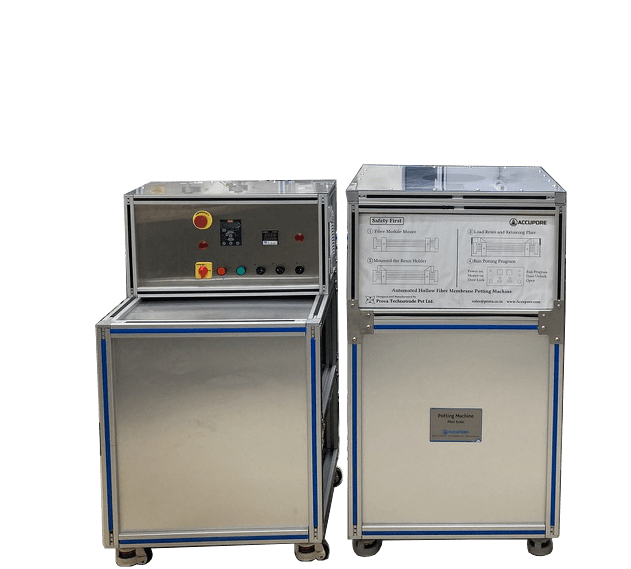

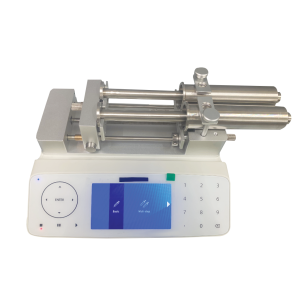

We also specialize in hollow fiber membrane fabrication equipment, offering fully customizable spinning rigs that support single or multi-bore extrusion, adjustable air-gap control, and integrated quenching and take-up systems. These rigs are modular, enabling researchers to switch easily between polymer types, geometries, and spinning conditions. Our setups support advanced spinning techniques, including dry-jet wet spinning and wet spinning, with options for post-treatment stations such as solvent exchange, annealing, and coating.

In addition, we are developing rotary jet spinning systems, an emerging technology that allows for solvent-free, high-throughput nanofiber production. This method opens up new possibilities in ultrafiltration, biomedical applications, and gas separation by enabling fine control over fiber morphology without the need for traditional spinnerets.

Our equipment is built for precision, reliability, and adaptability—allowing our partners to scale from research to pilot and commercial production with confidence.